PROJECT NUMBER: 1702-10

PROJECT TITLE: LOCH LEVEN PATH UPGRADE

DATE: 20th March 2017

DURATION: 2 weeks

RELATION TO THIS PROJECT: This project required the upgrading and repair of sections of path, which required logistical planning to access points/ material drops in several locations/ specialist small plant and operators/ communication with landowners/ various movements along the existing path with the plant.

The Client awarded SCOTFAST the contract to carry out maintenance works, and path upgrading works around Loch Leven. The works included scraping off loose materials from the existing path and scratching the surface to break up the surface before raising and widening the path across several sections.

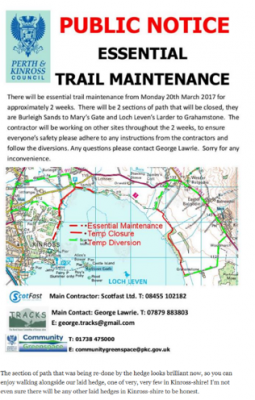

A notice was attached to each access point weeks before work being carried out to alert path users to upcoming works and usable diversions.

A major part of the works included contacting surrounding landowners for access routes and material storage points before works commencing and installing signage at all access points and barriers when required. The Client had good relationships with most of the landowners around Loch Leven, and we aimed to keep it that way.

Around 260 tonnes of material was delivered to the main point at a local farmyard and delivered to three different locations across the works via tractor and trailer to minimize travelling distance on site with small plant along the existing path. SCOTFAST made sure to restore all used access points to a satisfactory condition on completion of all works, and spread remaining type 1 in the farmyard and compacted as a goodwill gesture.

The site was very tight and required a constant watch for members of the public walking or cycling within the works area and we had to ensure that all plant was stationary when members of the public had to pass. SCOTFAST managed this with signage, barrier fencing and a full-time banksman to assist our excavators and dumpers when working.

Access and choice of plant were very limited with our client the Client setting a maximum plant width of 1.2m across all the works; This meant hiring a small 1-tonne dumper and 1.5-tonne digger to meet this requirement.

The nature of the works required all plant to be moved several times completing each section one after the other.

We had an ongoing programme with the client and constantly communicated progress reports and added labour and resources to meet each section deadline when required.

We designed and fabricated our own 1.2m wide adjustable depth drag box in our workshop to ensure that the 125mm specified type 1 base was consistent across the new path. Our drag boxes have the capability to create profiles to suit any application including a raised centre section or controlled side slope. Once the path base layer of 125mm type 1 had been spread through our drag box, a 110 roller was used to compact the material to refusal, Rolling the left-hand side then the right-hand side and finally the top to give a raise centre profile to stop water from sitting on the path. When dust was at that point used as a final binding material, and 20mm was formerly spread across the top layer of the path utilising the small wheeled dumper and operative with rakes. Following this, the soil edges of the path are pulled in and broken up to give a nice finish with specific drainage points left low to allow rainwater to get away from the path.

Along the path, edge protection was essential, and SCOTFAST utilised our 6×6 quad bike with an extended rack to lay materials out and transport equipment safely and quickly to each location along the line.

Large 150mm diameter turning posts are driven in to the ground 600mm, or if require digging and packing to depth, the Existing path was then excavated back to allow 100x225x4200 timber boards to be secured to the face of the turning posts with 150mm wood screws. The turning posts had to flow with the current path and not visually impact on the area too much; all worked timber on the site is treated with an approved endsele treatment to make sure and keep the life expectancy of the timber.